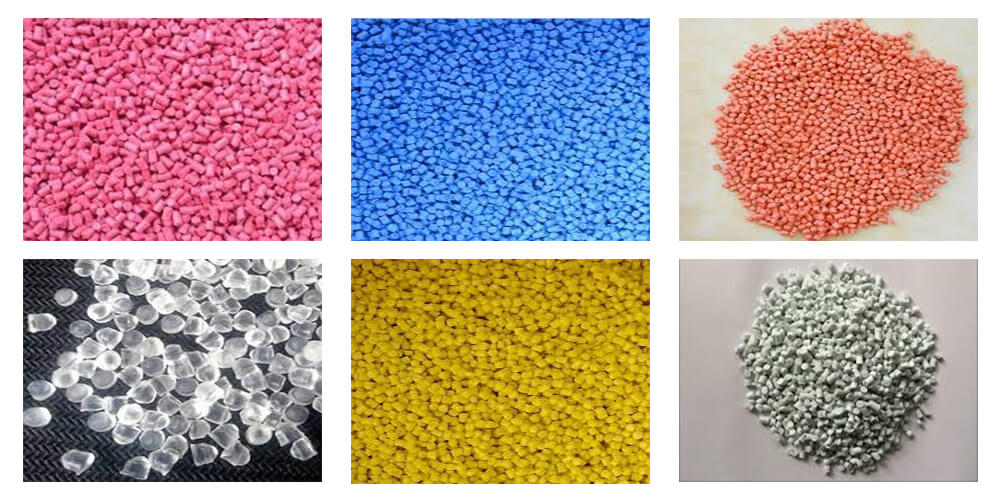

PVC pellets hot-cutting pelletizing line is mainly used to granulate the material of rigid PVC, soft PVC and waste PVC. It adopts die-face hot-cutting method, use pneumatic conversion and strong-wind blowing. The production capacity is from 100kg/h to 800kg/h. The precision of granulation is with good performance, high efficiency, installation and operation are easy and convenient.

Features

Advanced equipment, precise pelletizing and high producing capacity.

Conical double -screw extruder, very suitable to process PVC powder with high capacity.

Pelletizing type: hot-cutting on mould face, even cutting ensures good pellets shape.

Auxiliary machine: pellets cooling u& classifying.

According to customer’s materials formulation,we choose the screw with most reasonable structure,with the aim of reaching the best plastication status,as well as good material floating quality.

Parameters

Model SJZ-51/110 SJZ-65/132 SJZ-80/156 SJZ-92/188

Screw Diameter (mm) 51/110 65/132 80/156 92/188

Screw Quantity (mm) 2 2 2 2

Screw Speed (rpm) 1-34.7 1-34.7 1-36.9 1-32.9

Effective Screw Working Length (mm) 1070 1440 1800 2500

Main Motor Power(kw) 18.5 37 55 90

Barrel Heating Power (kw) 18 24 36 86.8

Output (kg) 80-150 150-250 250-400 500-600

Center Height (mm) 1000 1000 1000 1200

Weight (kg) 3500 4000 5000 10000

Dimension (mm) 3620×1050×2157 4235×1520×2450 4750×1550×2460 6725×1550×2860

Appliction